©Delfa

Concept development for a manual workstation for assembly of position sensors

Improving efficiency, preventing errors and improving quality through best practices and innovative solutions

CHALLENGE #1

There are potential for optimisation

CHALLENGE #2

Efficiency gains have so far been under-exploited

CHALLENGE #3

Working methods need to be reconsidered

About the project

Project objectives

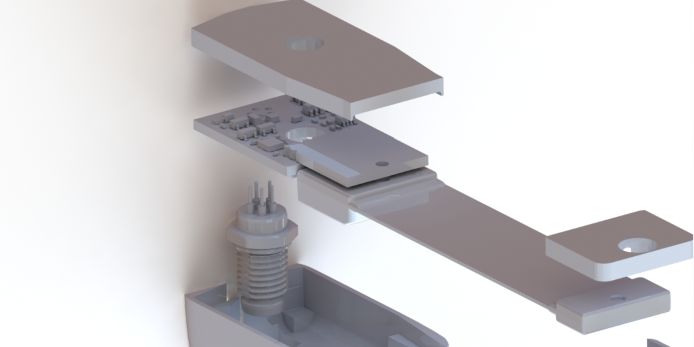

The aim of the project was to develop a concept for a manual workstation for the installation of position sensors. As it was a new product, there was no assembly station so far. The challenge was to increase the efficiency of the assembly process, minimise assembly errors and ensure product quality.

Baseline

The project started with a comprehensive analysis of the existing product structure. On this basis, the assembly process was optimised and suitable equipment selected. Particular attention was paid to the customisation of products on a month-to-day basis in order to facilitate handling and to reduce clock times.

A key element of the concept was the application of the Poka-Yoke principle. This error-prevention method uses simple, often visual, tools to avoid errors from the outset. Examples are assembly and calibration aids that increase the repeatability of assembly operations and simplify the work process for staff.

These measures have significantly increased the installation efficiency so that the desired number of units could be achieved with the same quality of position sensors.

©Adobe Stock/266270137

DESCRIPTION OF COMPANY

The EDIH provided us with a super-analysis of our assembly process, including suggestions for optimisation.

Steffen Hau

Co-Founder Delfa Systems GmbH

©Adobe Stock/317671063

Approach

The project was based on best practice in assembly system planning. Initially, a comprehensive analysis of the product and its structure was carried out to identify weaknesses and identify ways to increase efficiency. An essential aspect was to design the product in such a way that it can be installed in accordance with the standard.

The processes and assembly sequence were derived from the product structure. An assembly flow plan was drawn up and an error possibility and influence analysis (FMEA) was carried out. The FMEA method is a systematic approach to identify and assess potential defects in a product or process and their impact. This analysis makes it possible to identify sources of error at an early stage and to define targeted measures to prevent them.

On the basis of these findings, the equipment was selected and the manual workstation was redesigned. The workplace has been redesigned, new equipment has been integrated, and filling and calibration aids have been introduced. These measures resulted in a significant reduction in assembly times and improved product quality.

Result of the project

The development of a mobile work station as part of the project resulted in a significant increase in the efficiency of the assembly processes for position sensors and a reduction in assembly errors. The use of new inputs and the targeted optimisation of workflows have made it possible to reduce clock times and increase product quality. The consistent application of the Poka-Yoke principle and the integration of assembly and calibration aids increased the repeatability of the assembly processes and made it easier for staff to handle them.

The measures implemented resulted in a significant reduction in the duration of the assembly and guaranteed an efficient and error-free process. In addition, the project has provided valuable insights to serve as a basis for future digitalisation projects. This will ensure sustainable improvement and innovation in the assembly processes.

The result of the project is a manual workplace concept that not only minimises assembly errors, increases productivity, improves product quality and customer satisfaction, but also forms the basis for sustainable improvement and innovation in assembly processes.