©Adobe Stock/481445980

Enterprise resource planning system (ERP)

One small step towards digitalisation, one giant leap towards demand planning!

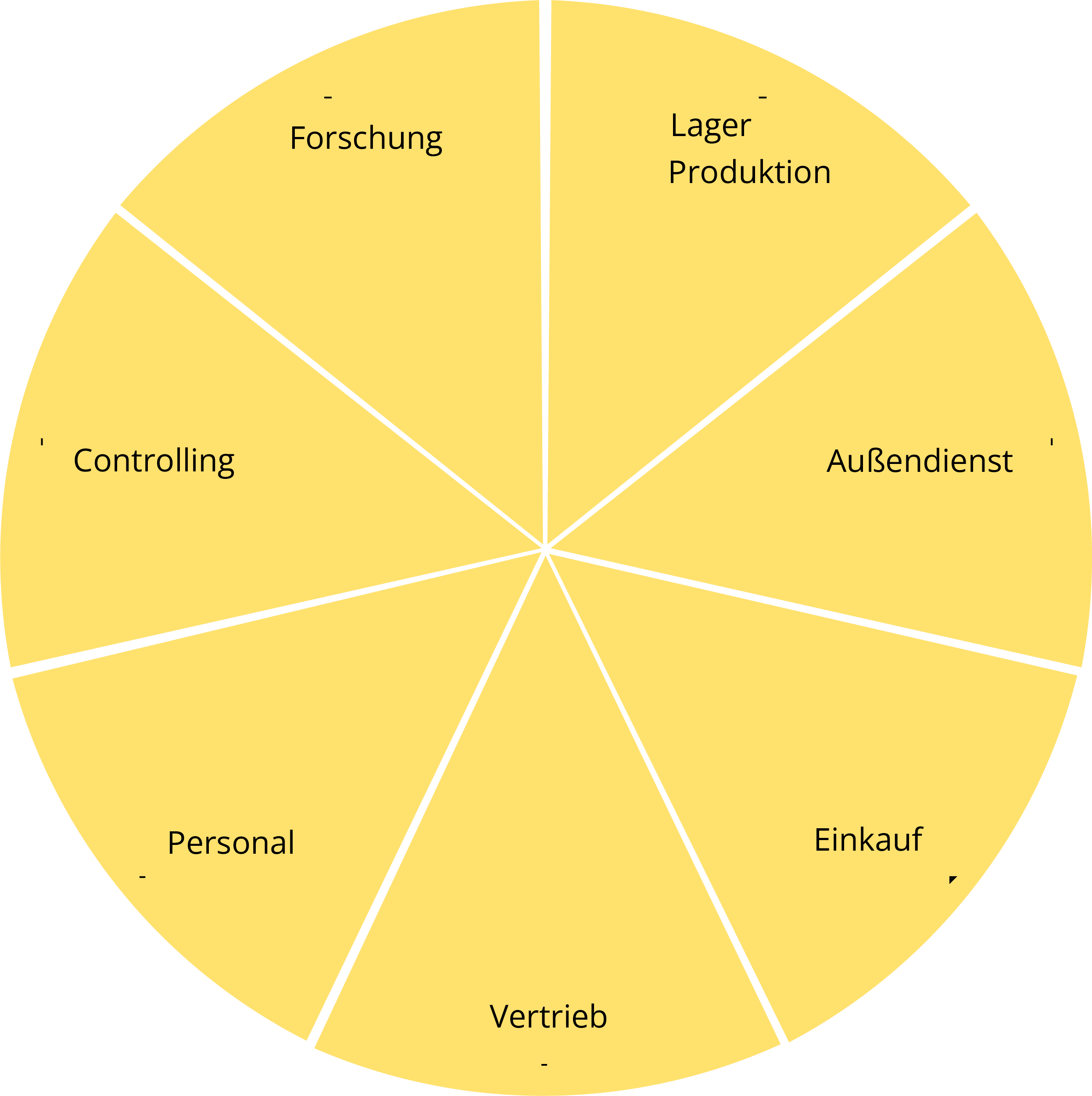

An enterprise resource planning system (ERP system) provides cross-functional support for all of a company’s business processes. It consists of modules for the areas of procurement/materials management, production, sales, research and development, human resources, finance and accounting, controlling, etc. The modules are linked to each other via a common database and thus enable planning support across all company levels.

The current status

Questions about Enterprise Resource Planning

What do I need for ERP?

These are costs for materials and services.

plus

License fees for the software.

online

enterprise solutions, a license starts at EUR 15 per user & month

Basically, the company needs an Internet connection.

Who can do ERP?

There are two solutions from ERP.

On-premise ERP:

Licenses are issued to specific persons and the software is permanently installed on a computer.

The computing power runs on the company’s own or rented servers.

Who can

N, i

is strongly dependent

on who

who owns a license and the software.

Cloud ERP:

Through a stable internet connection with a good web browser (e.g. Firefox, Chrome, Microsoft Edge)

cloud-based applications can be accessed from anywhere.

Anyone who is granted access can use the system.

What can ERP do?

The possibilities can be expanded with modules. As the name suggests, the basic functions related to the resources of a company.

— Operating materials

— Capital

— Work processes

— Personnel

— Resources

The The elements are planned, controlled and monitored in the ERP system.

Possible application scenarios

Step-by-step introduction

STEP1 Selecting the provider

In which area should the ERP system be used?

Which parameters should be recorded and monitored?

How many people should have access?

Step 2: Process overview

Create a small team of specialists from the various areas and positions.

You should include all processes that are to be adopted.

Step 3: Test environment

TRY to apply the processes from step two.

Formulate good and bad aspects.

Step 4: Customisation

Make small software updates with the

standardised

processes and collect master data that is required. Clean up the master data and enter it into the system.

Communicate the status of the project. Keep your colleagues up to date.

Step 5: Documentation & training

Use tips to highlight the best aspects of the software.

Train your employees and ensure that they work with it continuously.

Step 6: Real system

The specialists from the ERP project becomes the contact persons for application problems in the software.

Step 7: Updates

Add further processes with software iterations.

The strengths of the software are only recognised with regular use

and asks for more.

Smaller updates can be introduced if employees make improvements.

Opportunities for SMEs

Contact us

Keep an eye on the most important SME-relevant technologies with our technology radar!