©HERGES Stahl- und Blechbau GmbH

More accuracy, less burden: AI-assisted calculation in special-purpose machinery

CHALLENGE #1

How can the length of the process be calculated in the simplest and most reliable way possible?

CHALLENGE #2

Can the duration of the process be reliably predicted using an AI model?

CHALLENGE #3

Can Herges improve the AI model independently even after the end of the project?

About the project

Project objectives

For over 80 years, HERGES Stahl- und Blechbau GmbH in St. Ingbert has stood for artisanal precision and business continuity. As a family-run company, HERGES specialises in the production of welded steel and sheet metal structures, mostly unicerts, which are produced according to individual customer requirements. However, despite this long experience, the company faced a key challenge: How can manufacturing times and costs be calculated precisely in order to produce competitive and at the same time profitable offers?

Baseline

The calculation of supply is a decisive factor for the success of a company in the special machinery sector. Over-optimistic estimates lead to low prices and jeopardise the viability of a project. Too high bids, on the other hand, risk losing orders to competitors. Until now, the calculations in HERGES were mainly based on expert knowledge and manual estimates of staff, machine and material costs. However, precisely in the case of individual production, where almost every product is a unicate, precise prediction of production times was difficult.

Specific problems:

- Precision: How can staff and machine costs be better predicted to minimise inaccuracies in the calculation?

- Time spent: How can the burden of producing precise offers be reduced without compromising quality?

Initial internal attempts to manually record manufacturing times showed deviations of up to 30 minutes for identical components. This made it clear that a purely manual data collection was not sufficient to provide reliable data for the calculation.

©HERGES Stahl- und Blechbau GmbH

DESCRIPTION OF COMPANY

The EDIH team’s expertise in modelling the time-recording system and AI-based data mining has given us valuable impetus. Building on this, we can now implement further improvements in a targeted manner.

Daniel Krauser

Executive assistant

Approach

To address these challenges, HERGES cooperated with EDIH Saarland. The target: Develop a digital solution that accurately records production times and uses Artificial Intelligence (AI) to forecast supply calculations.

Step 1: Systematic data collection

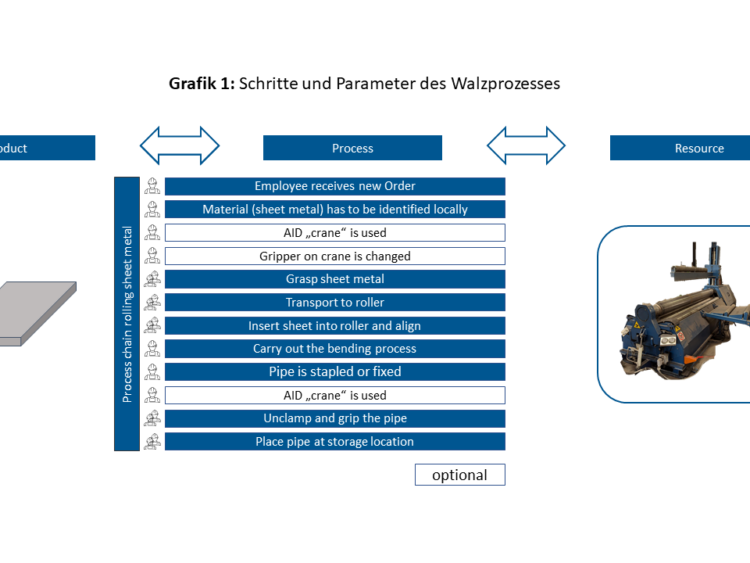

The rolling process for sheets was selected as a pilot process (Figure 1). This process has been broken down into individual steps, such as:

• Material identification

• Transport to roller

• Placing and shaping of the sheet

• Implementation of the bending process

• Stacking or fixing of finished pipes

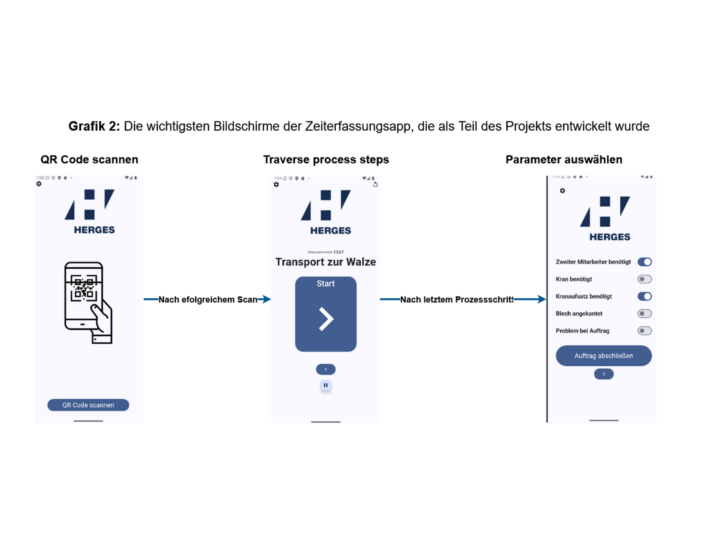

To digitalise time recording and make it user-friendly, an app was developed that allows staff to record the process steps by QR code scan (Graph 2). The app was developed in close cooperation with staff to ensure a high level of acceptance. After scanning the QR code, the staff could go through each process step and enter relevant parameters such as sheet thickness, width or diameter.

Step 2: Development of an AI model

The data collected was analysed to identify links between parameters (e.g. sheet thickness) and production times. A correlation analysis showed that the sheet width in particular has a significant influence on the production time (Graph 3). Other factors such as pipe diameter or sheet thickness played a minor role. This confirmed that there were more complex contexts that could not be explained by simple analytics – a clear indication that an AI model was the right approach.

The AI model has been trained to predict manufacturing times based on historical data. The focus was on minimising the deviations of AI estimates from actual manufacturing times. The Root Mean Squared Error (RMSE) was used as a measure of accuracy.

Result of the project

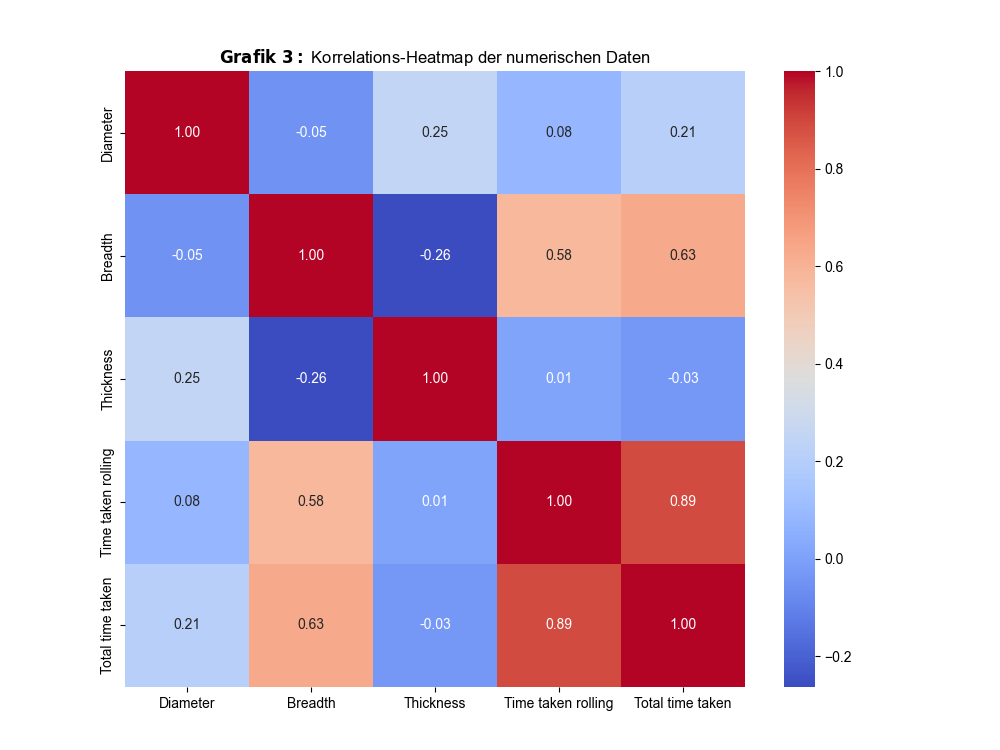

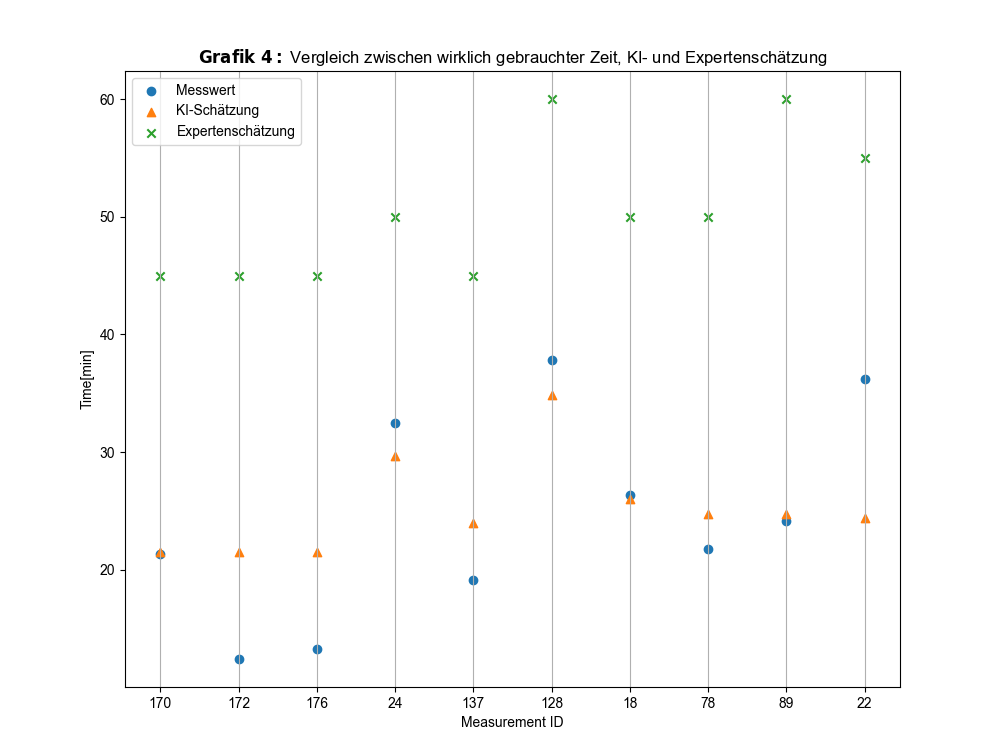

The introduction of digital time recording and the AI model brought measurable improvements (Graph 4):

Accuracy of AI compared to experts

- The deviation of the AI estimates from the actual manufacturing time was on average 4.54 minutes (15,2 %). In comparison, the experts’ manual estimates differed by 24.27 minutes (72.6 %) ab.

- Even with pure roll-out times, AI was, with a deviation of 3.81 minutes (16.5 %) twice as precise as the experts (deviation: Minutes, 39 %).

Putting it into practice on a day-to-day basis

The AI tool has been seamlessly integrated into everyday work. Employees can now predict manufacturing times for any sheet dimensions by entering parameters such as pipe diameter, sheet width and sheet thickness. To ensure the plausibility of the AI forecasts, each estimate will display the 10 most similar historical orders – including the times actually measured. This allows employees to immediately recognise deviations and manually adjust AI estimates.

Economic benefits

- Cost saving through more precise calculations.

- Time savings when drawing up the tender.

- Investing in the future: HERGES plans to extend the solution to other production areas such as welding and assembly. In addition, one staff member will be specifically recruited for the digital development of the solution.