© Wegenerhardtechnik GmbH

Smart robotics for detecting, maturing and sorting hardness parts

CHALLENGE #1

Wide applicability: How to develop a flexible and scalable automation system that can easily be adapted to new parts types?

CHALLENGE #2

Usability: How to ensure that the system is user-friendly and can be used by untrained staff?

CHALLENGE #3

Integration and efficiency: How can the system be seamlessly integrated into existing robotic processes to automate monotonous and time-consuming tasks and increase efficiency?

About the project

Project objectives

The project aimed to develop an innovative solution for automated detection, tyres and sorting of different hardness parts. The system should be accurate, reliable, flexible and scalable to adapt to new parts types. Another focus was on user-friendliness, so that it can also be easily used by untrained staff and minimises the induction time.

The framework should be seamlessly integrated into existing robotic processes to ensure continuous automation. The automation of monotonous tasks aims to increase efficiency and improve working conditions, allowing staff to focus on more demanding activities. The project promises to increase productivity and quality in manufacturing.

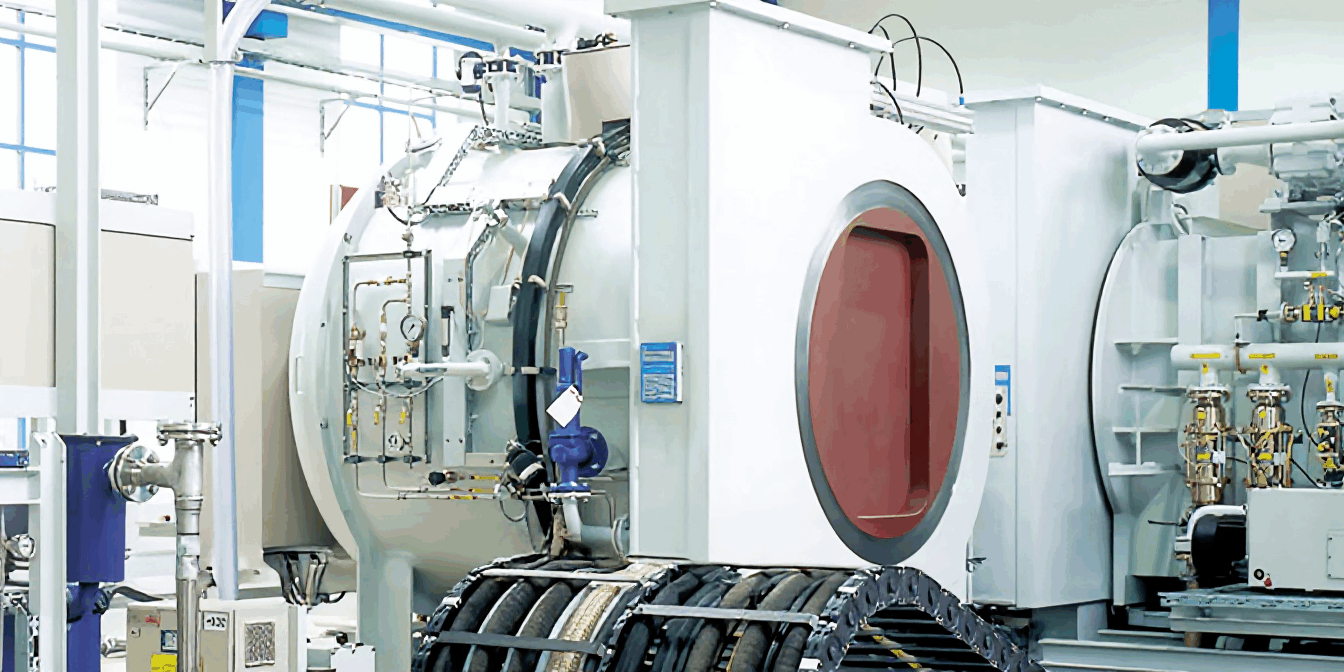

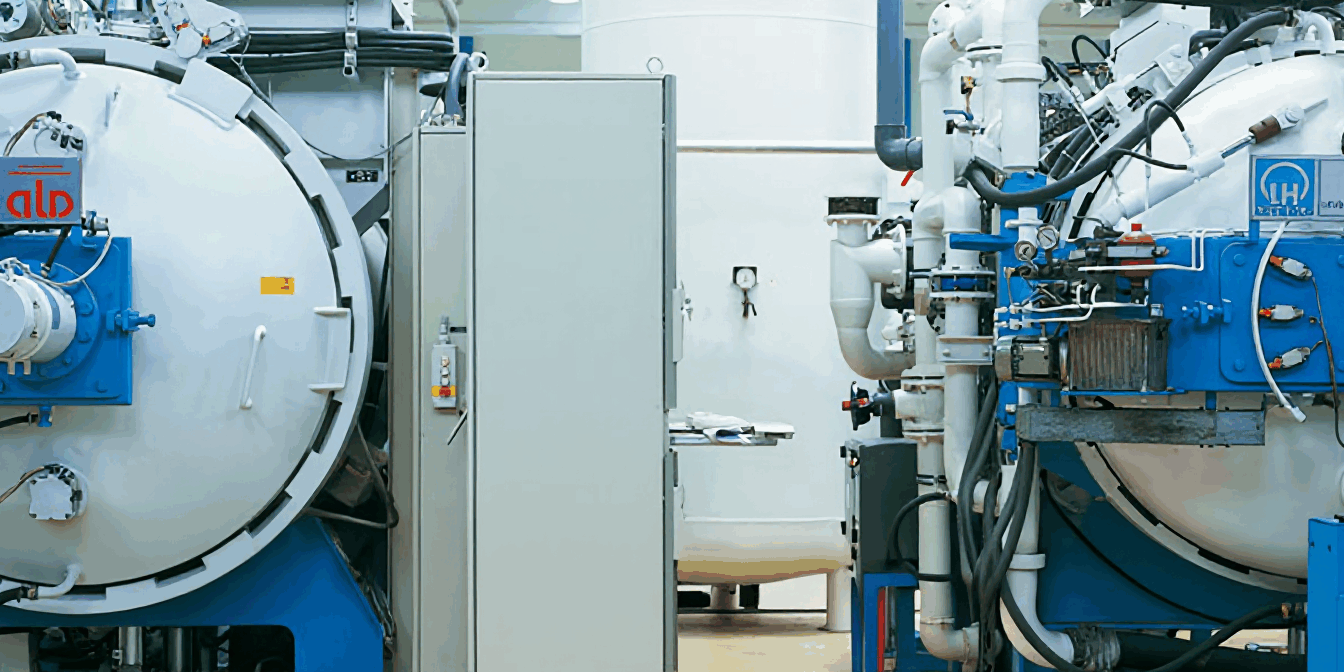

Baseline

The service provided by Wegener hardening engineering includes, inter alia, the hardening of metallic components. The hardness parts are delivered in a disorderly manner and must be ordered manually in another basket (hard basket) for the hardness process. The result of the manual process is the provision of hardness parts with a defined position and orientation. This process is a repetitive and time-consuming process that retains valuable labour and thus significantly limits the efficiency of production. In order to increase productivity, existing inputs, such as a 3-axle portal robot, should be considered and their use evaluated.

A key challenge in automating this process is the precise identification of components and the determination of the ripening positions, especially in the case of geometrically complex hardness parts that are in bulk. Reflections and geometric variations of the parts also make automated detection and handling more difficult. These factors require the development of a reliable and flexible system that can adapt to different types of parts while remaining user-friendly.

DESCRIPTION OF COMPANY

Cooperation with the Saarland EDIH was worth Gold: We have understood innovative technologies in a practical way, tackling challenges efficiently and creating real added value for our production processes.

Dr Simon Hechler

Head of Production at Wegenerhardtechnik GmbH

Approach

The project was implemented in several steps. First, technical analyses were carried out to define the requirements for an identification and ripening system. Various camera systems and grips were tested. As no suitable plug-and-play solutions could be identified, a prototype for validation was developed following the analysis and definition of the requirements.

As part of the development, additional parts, such as brackets and grab bakers, were initially designed and manufactured. The 3D object detection was then tested and evaluated, as well as the identification of suitable greifposs. Specifically adapted object detection algorithms, based, inter alia, on YOLOv8, were used to reliably identify the hardness parts. Even in the event of overlaps, these allowed for a precise location of the parts, so that the robot could work safely. A particular focus was placed on the recognisability and maturity of the individual components. Identified vulnerabilities, such as disruptive reflections, have been specifically addressed through optimised lighting techniques and algorithmic adaptations. Finally, camera detection was linked to the robot system to enable parts to be matured, removed and positioned in an automated manner.

Result of the project

The project shows promising progress and exciting challenges. Component recognition works reliably and the robot has been successfully integrated into simple processes. However, the handling of bulk material still poses difficulties, especially in the case of irregular geometries. More complex and precise solutions are needed.

Further development needs were identified and a human-robot collaboration scenario was assessed as part of a feasibility assessment (robot as assistant). The following topics were addressed:

1. The robot should be able to anticipate the process and submit components or tools. For this purpose, it was assumed that the robot or the artificial intelligence behind them were aware of the processes in scope, so that a) process recognition is established on the basis of (a) the progress of the process is established or (b) a tool is provided upon request.

2. In addition, the robot should in particular be able to identify tools by means of upgraded sensors (camera), to produce and return to the staff member. However, these processes are to some extent standardised, so that these routines can be taken over by the robot using AI and standardised processes.

3. In this context, a speech recognition application/voice commands to perform tasks in real time has been tested. Natural language orders were recorded and translated into robot-ready instructions on the basis of Large Language Models.

4. After various standard players were tested and found to be unfit for some applications, a prototype for a grip or an extension of grip was developed, which helped to make certain tools more secure.