©Adobe Stock/456467038

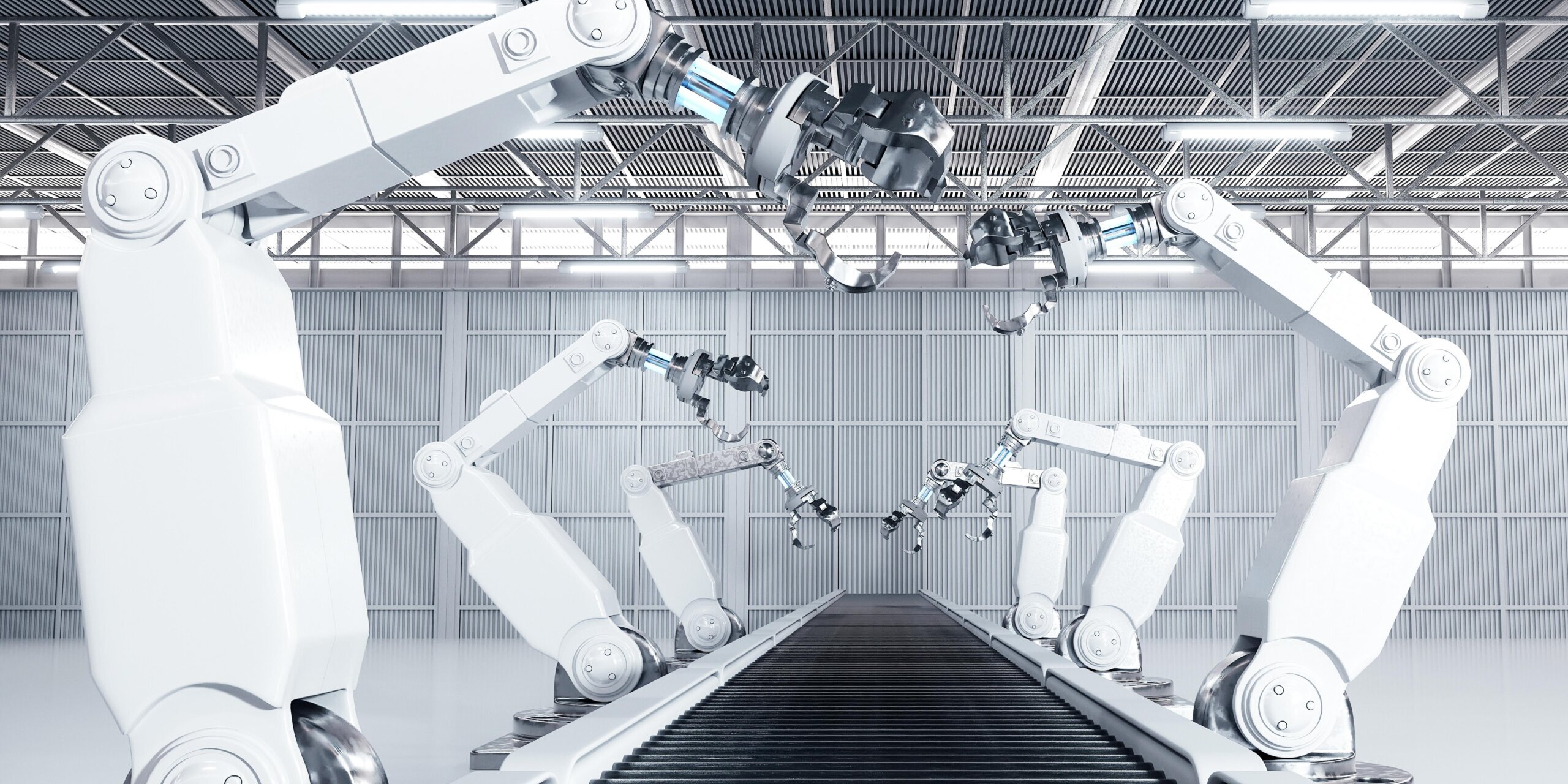

The next revolution in industrial robotics: Flexibility through Artificial Intelligence

Industrial robotics is facing a profound transformation. Robots have so far been used mainly for repetitive tasks with high precision requirements but little need for flexibility. However, new technological developments open up a completely new dimension: The robots of the future will be much more flexible, smarter and more versatile.

Traditional strengths and their limits

Industrial robots are nowadays to be taken away from modern manufacturing processes. They carry out tasks such as pick-and-place, spot welding or jet operations. Their strengths lie in the high repeatability accuracy and the ability to move heavy loads accurately along predefined paths. However, these tasks are usually highly standardised. Any deviation from the programmed ideal environment often leads to the discontinuation of the process.

For instance: A robot is programmed in such a way that it stacks parcels on a pallet. For this to work, both the pallet and the packages must be provided exactly at the expected positions. Even small deviations can cause the process to fail, unless previously cumbersome ancillary systems, such as camera-based detection, have been programmed. Flexibility? Not applicable.

Modern robotics: Precision, force control and the path to cognitive flexibility

Modern robots are today able to take on tasks that require a high level of precision and precision. Through force-controlled control, they can, for example, perform adaptive and case-specific grinding processes. These grinding applications are considered adaptive because the points to be processed are initially automatically identified. On the basis of this detection, the grinding parameters are dynamically adjusted, such as the press pressure, the speed of throwing or the tool position. The processing path can also be customised to respond flexibly to different geometries or workpiece tolerances. These activities have so far been reserved exclusively for humans.

Robots are also increasingly used in the area of demanding filling processes for products with very narrow tolerances. For example, conventional force regulation algorithms or machine learning approaches are used to control the robot on the basis of the resistances that occur in such a way that there are no collisions within the strict tolerance limits.

Other examples of modern robot applications can be found in spatially flexible quality control. Equipped with camera systems, robots are capable of distinguishing similar objects or reliably detecting qualitative errors. In such cases, the robot conducts the camera itself and thus actively carries out the visual inspection. Artificial intelligence significantly expands the possibilities of robotics. It allows sensor data to be interpreted, images to be analysed and decisions to be made on the basis of the identified information. However, despite this progress, robots still need to be carefully pre-programmed to work reliably.

Real flexibility therefore requires a new generation of robots that can not only execute commands, but also autonomously capture contexts and make decisions. Only then will it be possible to use robots dynamically and intuitively in complex, changing environments.

AI as Game Changer

At the same time, the development of artificial intelligence is progressing rapidly. AI, i.e. the ability of computer systems to provide cognitive services, can already interpret images, understand language, make decisions or learn from data. Autonomously driven cars show impressively what is possible when sensor-based data, machine learning and decision-making logic come together.

So what happens if you combine robots and sophisticated AI?

Language models as a key technology

In particular, so-called generative AI models like GPT (known by ChatGPT), they have proven to be versatile tools. Such Large Language Models (LLMs) not only understand and generate language, but can also draw conclusions, analyse tasks or generate programme code.

For instance: A language model can derive an assembly sequence on the basis of a written product description, without a human being having to programme each individual step in advance. Language-based instructions to robots are also conceivable: ‘Place of the red box on the pallet’ – regardless of whether the box is referred to as ‘box’, ‘package’ or ‘container’. The model recognises the context.

Multimodal models: View, comprehension, action

It becomes even more exciting with the so-called multimodal language models, which can interpret not only text but also images or other media. Such models allow scenarios that have been unthinkable to date.

Let’s imagine: A robot, coupled to a multimodal AI model, ‘looks’ a workspace with different objects. A simple instruction is sufficient:

‘Pack all bottles in the large package, and all cans in the smaller’.

The model identifies in the picture scene which objects are bottles and cans, identifies the appropriate cartons and generates instructions for the robot on this basis.

Of course, physical requirements remain: The robot needs appropriate grips, must be able to refer to the environment, but the threshold for pre-programming explicit cases falls significantly. This will make the systems more agile, smarter and fit for all. And the development is going further. Specialised large-scale AI models are emerging, enabling robots to perform complex tasks using camera images alone. This includes, for example, the enclosure of tableware, the folding of clothes, or the opening of cabinets and drawers. The flexibility of these models is impressive. They function regardless of the structure of the dishwasher, of the garment in front of them or of the exact design of a handle. If this principle is applied to industrial applications, the potential is quickly demonstrated. Robots could in future carry out adaptive operations, reliably handle bended components, and operate different design switches or mechanical controls without needing precise geometries or exact tolerances. These capabilities thus pave the way for generalistic systems that can operate safely and efficiently even in different production environments. The aim is to develop robots that can act as adaptable as humans and can reliably manage tasks even in slightly modified environments.

Conclusion: Robots become learning and context-sensitive

The combination of classical robotics and modern AI has enormous potential. Robots are becoming more precise and adaptive. They can interpret tasks autonomously, react to changes and interact with their surroundings, as required by a modern and competitive industry.

The next revolution of robotics is in full swing. Companies that rely on these new technologies today will be able to produce much more flexible and efficient tomorrow.

Experience the future of robotics live on Innovation Day – Robotics meets AI: Practical applications for flexible production and assembly

Want to learn more about the use of modern robotics and artificial intelligence in production? Then we invite you to our Innovation Day Robotics meets AI – practical applications for flexible production and assembly Poland. The event will be held on 24 September 2025 from 08:30 to 15:30 instead.

As part of the Innovation Day, we will present you with innovative and practical solutions for industrial manufacturing. This includes, but is not limited to, robotic looping, quality control with image processing and sensor-based robot control. Look forward to exciting live demonstrations and concrete application examples from industry.

Finally, you will have the opportunity to address your individual business problems directly to our team of experts. It does not matter whether you are already using robots or just thinking about starting automation. We are pleased to support you on the path towards a flexible and future-proof production.

You can register here: https://edih-saarland.de/de/events/innovationstag-ki-und-robotik/

Author

Dr Attique Bashir

ZeMA