3D printing

Prototyping made easy!

3D printing is an additive manufacturing process that is particularly suitable for prototype construction, individual items and components with complex geometries. Here, a computer-generated 3D model is divided into individual layers and then built up layer by layer. Depending on the printing process used, plastics, synthetic resins or metals can be 3D printed.

The current status

The 3D printing of plastics is already well researched and there are numerous suppliers of 3D printers in different price segments. In addition to the resulting print quality, the price also determines reliability and user-friendliness. The associated software is also often easy to use, as manufacturers focus not only on industrial customers, but also on hobby 3D printers. Plastic 3D printing is therefore suitable for SMEs. Note: The chances of one of your employees owning a 3D printer are relatively high these days.

Although 3D printing of metal (and other special materials) is already being used in industry, it is still an active area of research and its use is not trivial. A deep understanding of materials science and the printing process is required in order to select a suitable material and to print or handle it correctly. Due to the current relatively high complexity and acquisition costs, the use of metal 3D printing in SMEs is only suitable to a limited extent.

Technology and use

Technology description

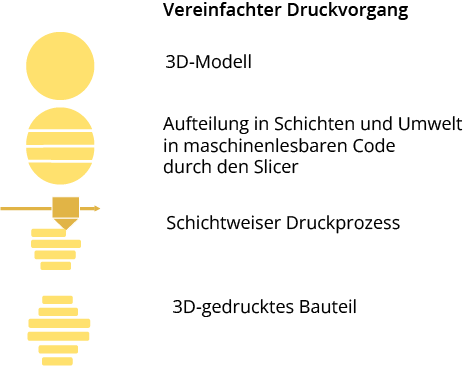

First, a three-dimensional model created on the computer is converted or triangulated into a suitable format, usually the STL format. The transformation therefore approximates the surface of the model using triangles. The model is then divided into individual layers by the so-called „slicer“ software, which is then converted into machine-readable code. The code generated in this way enables the 3D printer to produce the individual layers sequentially.

The form in which the respective layers are produced depends on the 3D printing process used. Two typical processes are FDM (fused deposition modeling), in which the filament (the material to be printed) is melted and extruded, and stereolithography (SLA), in which either resin is cured by UV rays or powder is melted by lasers or electron beams. Depending on the end application, 3D printed parts must be post-treated (surface quality, dimensional accuracy, material properties).

Step-by-step introduction

Step 1: Selecting the area of application or the framework conditions

Step 2: Selecting the 3D printer and associated software

Step 3: Workplace design

Step 4: Elimination and training of employees

Opportunities for SMEs

Contact us

Keep an eye on the most important SME-relevant technologies with our technology radar!